Lead End Material Selection Aid

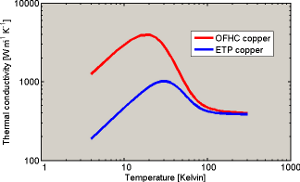

Thermal conductivity

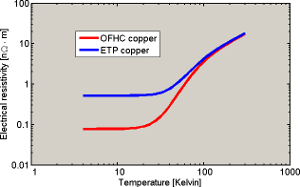

Electrical resistivity

Cu 110 Grade: ETP

ETP copper is at least 99.9% pure and is therefore a suitable choice of meterial for general electrical applications.

Cu 101 Grade: OFHC

OFHC copper is at least 99.99% pure and is therefore a suitable choice of meterial for applications at low temperatures.

At low temperatures impurities and lattice defects dominate the behaviour of the electrical resistivity and the thermal conductivity. Different grades of copper are classed according to their residual resistivity ratio (RRR) which is the ratio of the resistivity at 273K to that at 4K. In the plots presented below the ETP copper has RRR=30 which is chosen to represent the lowest grades. ETP copper is usually supplied with higher RRR. Similarly the OFHC copper has conservative value of RRR=200 and most commercial suppliers will exceed this.

When selecting the copper grade for the lead ends it should be noted that above about 50K there is very little performance difference between the grades. If a lead end is to be stationed at a temperature above this then it may be more cost effective to make that end from ETP copper.

Nb (99.99% pure)

Niobium is one of the few Type II elemental superconductors and has the highest critical temperature for any element (9.26K). Niobium may be an appropriate material for a lead end stationed at a temperature below 9K. This may assist in reducing the low temperature heat load.

Niobium also has high critical fields. These are very dependent on temperature and purity with Hc1 varying from 0-0.2T and Hc2 varying from 0-0.8T. This makes Niobium an appropriate choice for cold lead ends that may be exposed to high fringing fields.